- Angle Tower Processing Machines

- Steel Structure/Building Processing Machines

- TPD Series CNC Plate Drilling Machine

- TPHD2016 High Speed CNC Drilling Machine

- TPHD2020/TPHD2525/TPHD3030 High Speed CNC Drilling Machine

- TPHD Series Multi-spindle CNC High Speed Drilling Machine

- TPLD2020/TPLD2525/TPLD3030 Normal Speed CNC Drilling Machine

- TPLD Series Multi-spindle Normal Speed CNC Drilling Machine

- TPM2020/TPM2525/TPM3030 High Speed CNC Drilling Machine

- TSWZ700 CNC H Beam Drilling Line

- TSWZ1000/TSWZ1250 CNC H Beam Drilling Line

- TBS Series Band Sawing Machine

- TDJ Series CNC Angle Rotation Band Sawing Machine

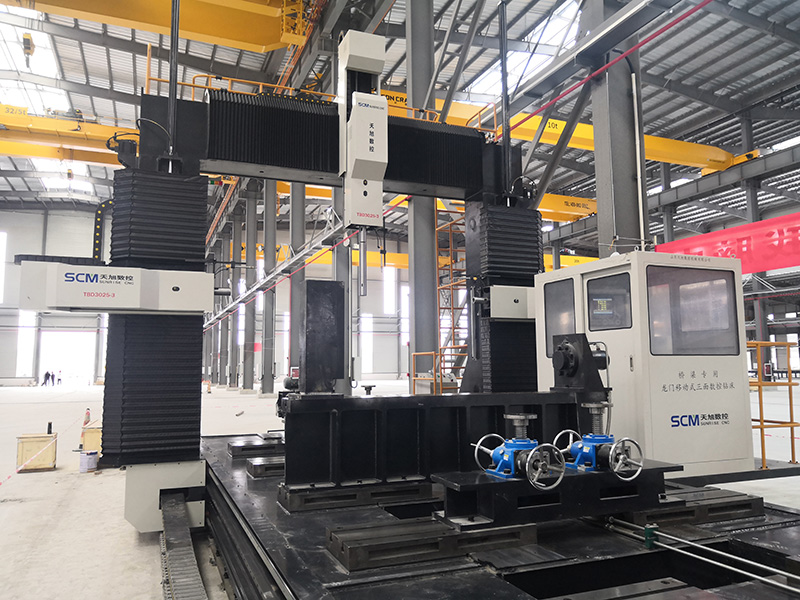

- TBD Series Gantry Movable CNC Drilling Machine

- TPL104 Hydraulic CNC Punching Machine For Steel Plates

- TPL108 Multi-station Hydraulic CNC Punching Machine For Steel Plates

- TPP103/TPP104 CNC Hydraulic Plate Punching & Marking Machine

- TPPR103/TPPR104 Enhanced CNC Hydraulic Plate Punching & Marking Machine

- TPPD103/TPPD104 CNC Hydraulic Plate Punching, Drilling & Marking Machine

- TPPRD103/TPPRD104 Enhanced CNC Hydraulic Plate Punching, Drilling & Marking Machine

- TBM38 CNC H Beams Beveling Machine

- TBM55 CNC H Beams Beveling Machine

- CNC Plasma Cutting Machine

- DZL600 Single Spindle Beams Drilling Machine

- TPL9004 CNC Hydraulic Punching,Marking & Shearing Line For Flat Bar And Channel

- TPL9004 CNC Hydraulic Punching,Marking & Shearing Line For Flat Bar And Channel

- TPHD3020 CNC High Speed Drilling Machine

- HDZL600/HDZL1200 Single Spindle High Speed CNC Beams Drilling Machine

- Large Steel Plate Processing Machines

- Boiler/Pressure Vessel/Heat Exchanger Processing Machines

- Bridge/Parking Garage Structure Processing Machines

- Petroleum/Chemical Industry Processing Machines

Used for drilling of lager size H-beams and cased beams.

1. Three slipway type CNC drilling spindles respectively on the up, left & right, can drill holes simultaneously.

2. CNC & PLC systems, CRT display.

3. Eight CNC axes.

4. Coordinates of drilling can be directly transferred to CAD/CAM.

5. Automatic chip removal, circular coolant.

6. Laser alignment conveniently.

Model |

TBD200/3 |

TBD1010 |

|

Workpiece size |

Max. section size (W×H) (mm) |

2000×1000 |

1000×1000 |

Min. section size (W×H) (mm) |

1000×400 |

300×300 |

|

Max. length (m) |

16 |

2~20 |

|

Drilling unit |

Type |

CNC slipway type |

CNC slipway type |

Quantity |

3 |

3 |

|

Max. drilling dia. (mm) |

Φ50 |

Φ50 |

|

Rotation speed (r/min) |

120~560 Frequency conversion |

120~560 Frequency conversion |

|

Axial stroke (mm) |

600 |

600/400/400 |

|

Feeding speed (mm/min) |

0~4000 |

0~4000 |

|

Motor power of spindle (kW) |

5.5 (×3 ) |

5.5 (×3 ) |

|

Power of servo motor (kW) |

1 (×3 ) |

1 (×3 ) |

|

Movement of gantry (X axis) |

Stroke (m) |

16 |

20.5 |

Max. moving speed (m/min) |

8 |

8 |

|

Power of servo motor (kW) |

2 (×2 ) |

2 (×2 ) |

|

Transverse movement of vertical drilling unit (Y axis) |

Stroke (mm) |

2000 |

1000 |

Max. moving speed (m/min) |

10 |

8 |

|

Power of servo motor (kW) |

1 |

1.5 |

|

Up and down movement of left/right drilling unit (Z,W axes) |

Stroke (mm) |

1000 |

1000 |

Max. moving speed (m/min) |

10 |

8 |

|

Power of servo motor (kW) |

1.5 (×2 ) |

1.5 (×2 ) |

|

Hydraulic pump |

Motor power (kW) |

2.2+0.75 |

2.2+0.75 |

Swarf-converor |

Motor power (kW) |

0.75 (×2 ) |

0.75 (×2 ) |

Cooling pump |

Motor power (kW) |

0.45 |

0.45 |

Power supply |

Total power (kW) |

35 |

40 |